|

If

you do not get earth ground at the wall receptacle it gets

challenging. Some people get earth ground through their audio

cable connected to an amplifier with a three

prong power plug.

This last method prevents you from using headphones as no earth

ground would be available. A Y-adapter at the theremin and leave

one side plugged into a turned off main amplifier with a three

prong plug

could work. If

you use a 12 volt battery (2

x 6 volt Lantern Batteries)

you could wire a three prong plug with only the wire connected

to the green ground terminal plugged into a wall receptacle.

Each board draws less than 30

ma. If

you are busking,

for earth ground drive a 3' or 1 meter metal rod into the soil

all the way so no one steps on it. Then dig around it and use an

alligator type clip to attach to it. Leave it there for

next time. (flowerbed) Earth

ground is

important because the theremin works with radio

wave energy

(RF) that will distort the sound if it has no way to leave the circuit

board. Yes your hand is a capacitance

effect but

there are many effects involved.

- when using

both boards together, do not

hook up power to both boards, use the J2 jack -

When first

connecting power to the board monitor the current for overload

indicating a mistake.

Power

Supply: For power the Phoenix is well filtered

and can use 12

volts AC, DC or a Switching power supply.

The two boards use less than 60 ma total and can drive a low

current accessory. Use a power source of 500 ma

or more, you

must get earth ground from somewhere. The

original home page lists many

components and things for your theremin build.

.

Board

3.04.20 Modifications

|

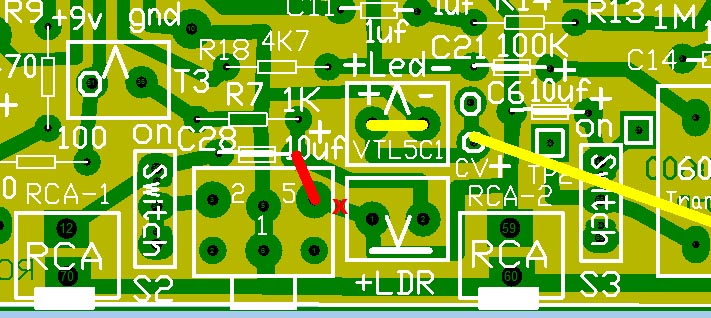

Fix

#1

Fix #1

This

is corrected on board date 4.14.20 and later

Do

this before stuffing parts

The 3.04.20

board needs a modification, cut the copper at the red

X with a razor blade. See PCB image at Fix #2 below

After the

parts are stuffed then add a jump wire across the pads with the red line.

This allows controlled audio

volume out the

breakout TRS jack on the left side of LDR.

Audio

and Power can pass board to board through the TRS J2 jack

using a TRS cable.

|

.

This is

viewing the board from the bottom side. Also view "Jumper" in

image below Fix #2.

Use a

drill bit in a drill or razor blade to break the x

copper

connection. Solder a wire across the pads of the red line

after you

mount the parts. Do

this before you stuff the board

|

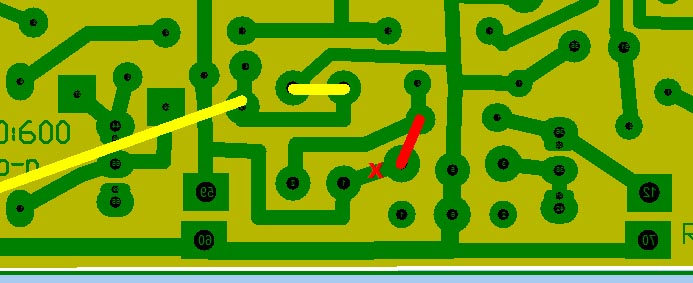

Fix-2

Fix #2

Do

this before stuffing the parts, see photo below,

at "Cut" use a razor blade to break the copper track.

Study board bottom against that picture. Use a marker, place a

black dot at spot. Back

to Index

Do these fixes after the board has been stuffed.

When the green

LED-1 is ON the

Vactrol should be passing an audio signal. The

CV+ to CV+ jumper wire must be installed seen as the white wire

on the actual board. Added to this wire can be a Mute Switch.

There

is a solder bridge across IC pins 1 & 2 near R38, Do this on

Pitch board, Volume Board I do something different. Other than

that both boards are the same. Pitch Board only uses 600:600

transformer while the Volume Board only uses the Vactrol.

Before

board is stuffed (see

Fix #1 above)

use

a razor blade or drill bit to break the copper trace between the

two pads where it says Cut.

Click on Picture to

Enlarge

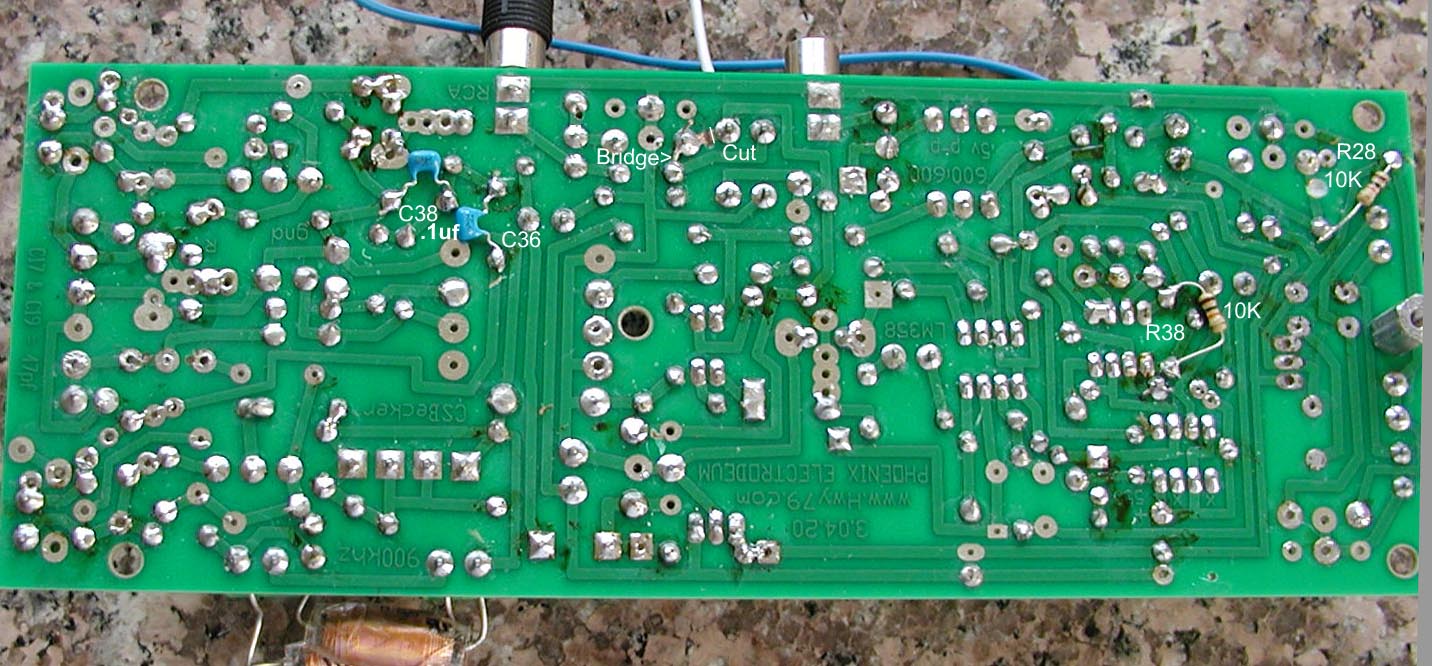

Bottom of

3.04.20 Pitch Board as of 8.20.20, Volume Board does not have

solder bridged IC pins 1 & 2 by R38

C38

is across C29- 470 uf &

C36 is across R9- 470 ohms &

R38 is across U2 pins 4 & 5 &

R28 is C9 plus side to ground to drain the charge on the

capacitor or it will latch up the 555.

Fix

#3

Fix

#3

Do

this fix "after"

the board has been stuffed.

When the green

LED-1 is ON the

Vactrol should be passing an audio signal. The

CV+ to CV+ jumper wire must be installed or attach a Mute switch

between here with wire

leads for a SPST switch.

Add a 4.7k resistor to

the two pads the red line touches so the green LED Off

at Null. (wait

on doing this)

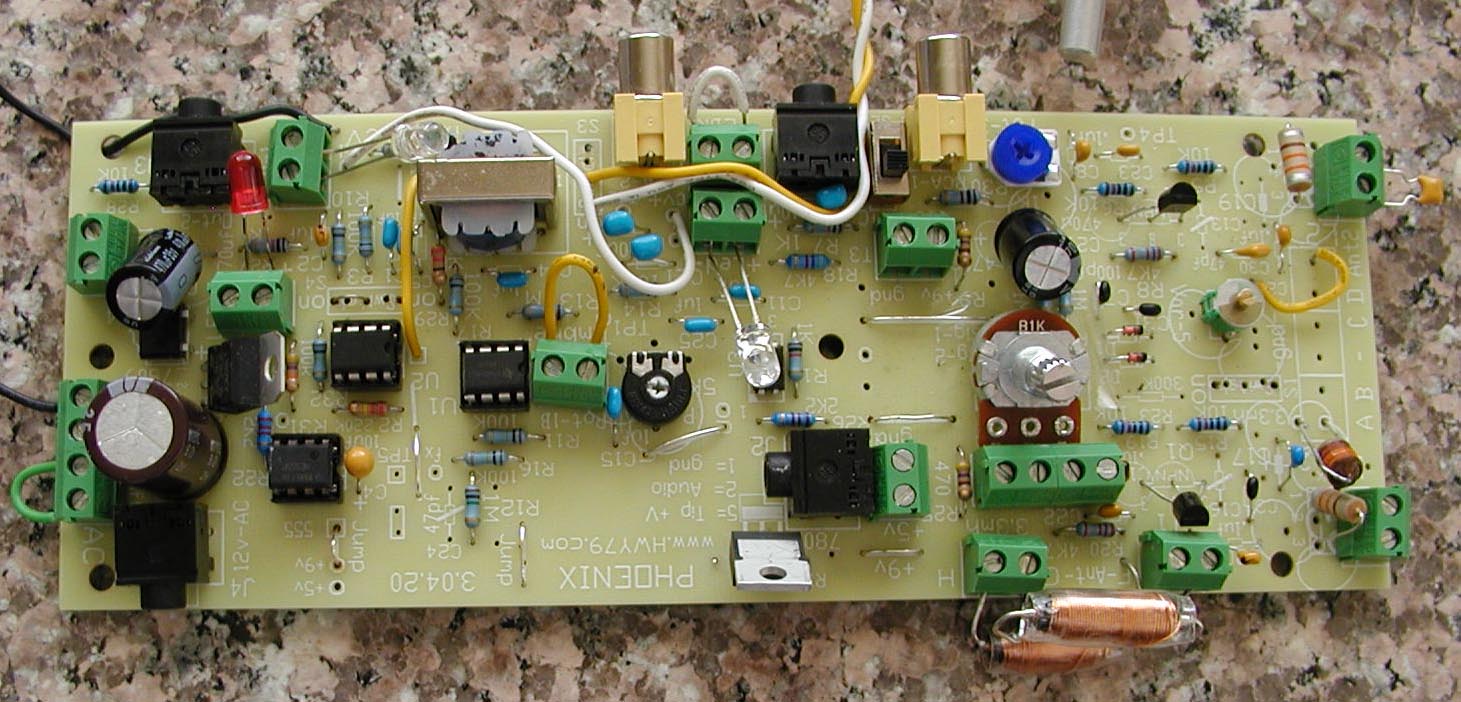

|

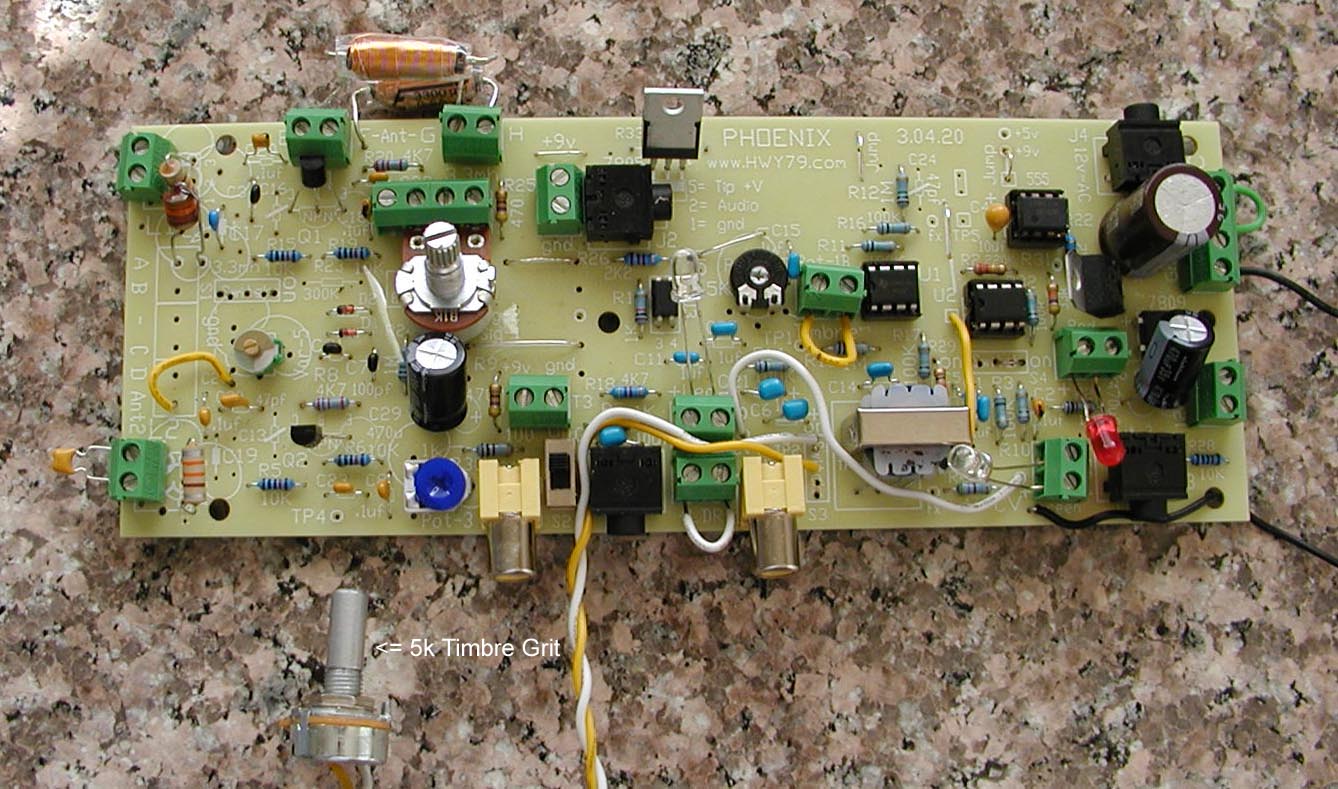

| The

yellow & white wire is Audio Out to my scope probe

to hang on. The green jumper wire on the lower left

corner closes the switch terminal contacts to the TRS power jack.

The

longer white wire is for the PWM to the Vactrol. The

green terminal on the left of the white wire is temporary

bypassing the uninstalled Vactrol. This allows the LED's

to work.

The C19

capacitor under the L2 is not mounted or

used. L2 is in the upper right corner of the

picture, looks like a big resistor. Try different values

of capacitors in the green terminal to the right side of L2-330uh

coil.

Start with 22pf then 33pf, etc. Tune the variable

capacitor and see if you hit Zero-Beat. Return

to correction 3.

index

page.

|

-

Right click mouse, click on "open image in new tab" to

get a close up views -

Fix

#4 Component

Value Changes, all on the left side oscillator section

Resistors:

R8 & R20 emitter resistors was changed from 4.7k to 3.3k

Capacitors:

C17 changes from 47pf to 10pf,

C22 changes from 47pf to 100pf

Inductors:

L5 3300uh

was added to the Volume Board antenna/loop side, this must be of the high

current type

like L4. Pitch Board setup is 330

uh with 4.8 Ohms resistance max for higher

Q

When

I design I watch her waveform on an Oscilloscope. All of these

changes fine tune her Classic sound or her natural voice that

begins at the antenna and has been illusive for 100 years to

most designers.

Issues

For Study

PWM

PWM -

Volume Control

setup demonstrates

a weak PWM, the waveform is solid throughout its

frequency range. In previous builds using IF Transformers the waveform would change

with the frequency change and some how changed the offset of the

waveform. It was rather scrappy but it worked. Needs

Study

The Vactrol LED

terminal + -

may be backward? If

so Vactrol will be mounted upside down.

Mount a LED on

the LED side of the Vactrol green terminal in place of the

Vactrol when experimenting.

It was more triangular and would

cause the signal DC offset to shift with frequency, similar to a

triangular wave form rising above the scope dc center line. Need to get back to this. Needs

Study

Idea: This

schematic looks promising.

(will

breadboard this circuit, apply it in the C1-1uf area in

place of S4.

I need the

offset to drift .4v to the negative side with a 0-1khz

response

-

a negative .4 volt deflection would be better than none -

Experimentation

will demonstrate the best approach. See Switch S4 below - Visit

How the Volume

Control Works

Switch S4

Switch S4

is not

needed. Where S4 was wire jump the center switch pad to

the right side switch pad which is Pin-3 of U2 LM358. Then jump Pin 1 & 2 of the

LM358

also with a deliberate solder bridge. (Picture

Coming)

LED

LED - Mouser

only carries the 3mm size. I prefer the 5mm and a bright Mcd.

Green

LED-1

remains

ON when sound is passing through the Vactrol is ON. Needs

Improvement

Pot-1b 100k is in

series with Pot-1a 5k, this is for fine Timbre or

Volume peak

trigger adjustment. This controls how much skew is on the upper

side of the audio wave form or even harmonics are introduced.

This can be a jumper wire instead of a Potentiometer while

diagnosing the build. Good

On the Volume

Control setup the L4-3300uh

Pitch side tuning

choke should

"not" be connected.

4.17.20

This needs

study with the addition of L5 3300uh high Q coil.

Electrodeum

Electrodeum

4.15.20

Connected the Electrodeum

and it distorted the audio wave shape. My first impression it is

loading down the L1

oscillator and not resonating in harmony with it. The only

change from previous builds is the fix ferrite coils. When the

Electrodeum works it is like On or Off when it comes to

linearity. There is no almost linear, it either works or it does

not.

Higher-Q

L1 & L2 coils needs to be tried for driving

the Electrodeum.

Electrodeum

Observations: Needs

Study

When I substituted

the Electrodeum with a 10pf capacitor to ground it stopped L1

oscillation.

If the L4

the antenna 3.3 mh choke is not a high current (High Q)

the Electrodeum does not work.

I need to test a Higher

Q L1 330uh

coil, another type is seen in the pictures next to the antenna

side of the board.

The resonant frequency of

L4-3300 uh in series with a 10pf capacitor to ground is 900 kHz.

Using a scope we

may be able to tell if the Electrodeum is functioning correctly

by sensing the antenna voltage? At the antenna should be 30

volts or more using very high impedance probe.

The

Electrodeum could be capacitive coupling back to the L2

oscillator.

4.17.20 Need

to test the EWS pitch antenna with the L4

3.3mh in series

as most will not have the spring coil. The Phoenix fits inside

the EWS wood box. I do like the idea of a fat telescoping pitch

antenna. This allows external adjusting to the environment and

keeping Pot-4 for Zero Beat centered. Need to test linearity in

this approach.

Thermal Drift

| Thermal

Drift:

In solid-state drift is caused by the slightest imbalance between the two RF oscillators, to be more specific mostly the difference

is in the behavior of PN junctions.

The drift effect is exaggerated by temperature change caused poor design internally that allows a heat source like transformers, regulators and too much design current flow; this is what causes the “unnecessary” warm up period. Then there is the effect of the outside room temperature changes. Solid-state theremin circuitry should always be at room temperature On or Off.

All graphs should choose the same single note like A4 440 Hz and graph frequency change against a highly accurate thermometer. This should be done “without” the Pitch Antenna connected as you only want to monitor the circuitry for stability. The antenna will add its own effect and why using a telescoping antenna is a better idea though I would not use one as I think they look too whippy. There are other ways to add small changes to the length of the Pitch Antenna to balance it against the

environment background.

My best results over the years could hold onto the same musical note over a 5 degree F room temperature change. In other words I set the musical note to A4 the night before and wake up to my theremin still singing on A4

440 Hz or very close when I got out of bed in the cooler

morning.

Surprisingly Vacuum Tube theremins have less thermal drift than solid state.

9.05.20

The

first thermal drift test is done with the antenna

disconnected. After that proves solid then redo the test

with the Electrodeum connected 1/4 the distance from the

bottom of the spring coil which has demonstrated the best

drift resistant connection.

Test

below with Pitch on the proper side of Null or Zero Beat

-

Room temp decreases and pitch goes up,

- turn Pot-3 - a bit CW to

reduce resistance -

-

Room temp decreases and pitch goes down, turn Pot-3 a bit

CCW to increase resistance -

-

Room temp increases and pitch goes up, turn Pot-3 a bit CCW to

increase resistance -

-

Room temp increases and pitch goes down, turn

Pot-3 a bit CW to reduce resistance -

Full CCW max resistance of

Pot-3 100 ohm. Pitch rises as room temperature drops is

wanted.

When

ideal the

musical note A4- 440 Hz will remain with little drift over a room temperature change of 5 degrees F.

|

The transistor PN junctions have capacitance that

varies with the voltage across them and temperature changes, similar

to a Varactor. The goal is to balance the behavior of the two

transistors so they behave as identical as possible in the

circuit.

The next area of

drift is the Pitch antenna's capacitance relative to the environment.

This is where a telescoping antenna comes in handy. Stretch or

compress the antenna to keep zero-beat centered on Pot-4 which

used for fine tuning.

Pot-3

is added to balance the voltage across both transistor PN

junctions in the

oscillator section. This is for thermal drift control. The very

low current through the transistors allows this to work. Needs

Study

My concern is the

Var-5 variable capacitor could add imbalance and cause

thermal drift?

I noticed once the pitch raced up or

down over time while sitting idle. Replacing squirrely

transistors with another set should eliminate this. Using transistor

sockets might

be wise to find the best transistor combination.

Another cause of

racing may be mechanical

like a loose capacitor in the L2 green terminal or Pot-3 or Pot-4 are defective or

may need a

shot of DeoxIT®

Fader F-Series –

Contact Lubricant for Conductive Plastic Faders and Controls

. (do

not use WD-40)

Microphonic

effect when tapping the board was cause by the capacitor in the L2

green terminal not being secure.

When tuning the Variable

Capacitor and

it seems like the Null or Zero beat point is in the same

direction you are on the edge of the capacitors range. You need

to add a bit of capacitance (3.3pf ?) to one side or the other

to better center the variable capacitor. You want to be at

Null or Zero beat

when the

variable capacitor along with Pot-4

1k is set at

half way.

The sweep range of Pot-4

can be reduced by adding a parallel 470 ohm resistor at R25

on the right side of the Pot-4

green terminal. When experimenting I like to work with a large

range.

A

grounded

shield above or below the oscillator

L2

section may reduce

distortion

from Pitch Antenna capacitive feedback and blocks 50/60 Hz hum. Placing

the PCB against a wood surface can cause issues. Needs

Study

Don PB here is

your original 2013 schematic

and here is latest 2020 schematic.

Future

Ideas:

4.16.20

Diode D2

mixer diode is for a future experiment. Two channels could be

taken and shaped independently using a second Audio section of

the board and be true stereo or mix back together for a fuller

sound. Needs

Study

Develop

the circuit for rapid ON with Volume hand so notes can be popped

ON with a swift movement of the hand upward from the volume

control loop. This triggering could also briefly increase the

amplitude of the audio signal a better pop-on effect. Volume

Enhancement concept. Needs

Study

Another

way is to touch the volume loop as in my design of Volume

Control this would stop the oscillator from oscillating and have

a similar effect. Currently this last approach is a bit sloppy

on recovery. Needs

Study

|