|

How to drill precise

locations for the holes

Template

PDF 194k

Print the Actual Size

Not every hole needs to be drilled Cut

away the two corners, "accurately" fold down on the line on three sides with

the text facing outward The

template is designed using a board space of .2",

if your standoff is taller add the difference above the +.

With the template in position, wrapped around the back side of the box,

center punch each hole of choice at the indicated + with a nail or center

punch, tap with a hammer. Remove template and drill at the appropriate

drill locations with the "proper drill sizes". Wear safety

glasses Notes

by Dana (SewerPipe)

The

1/2" holes A B C are a must for the main cables.

1. Use the 2 fluted

(flat) spade type wood bits

for the 1/2" holes.

2. Clamp a scrap piece

of wood to the back side of hole location. This will minimize the

wood “splintering” at break through.

3. If using hand drill,

carefully clamp the “Box” in a bench vice or clamp to bench.

4. Use “Both” hands

on drill motor. Run slow to medium RPM.

The Null tuning

shaft extender can face out of the box in either direction depending on the

direction you mount the Pot-4 on the circuit board. Preferably away from

the antenna side. The

Tuning Pot 1/4" shaft extender size uses a 3/8"hole. A wood thread insert can be

installed at the short pot location using a 7/16" (3/8") hole

for the tripod 1/4-20 mounting screw. Wood

Thread Insert Lowes Drilling the

3/8" hole a bit larger

at 7/16" for the thread insert was

recommended from product user comments. Also recommended was to thread a

1/4-20 bolt through the insert with double nuts to lock it in place while

inserting it. The

thread insert can be placed on the narrow side of the box mounted against

the tripod, then turn the tripod to have the broad side facing an

audience. You could also cut a 3" x 2.5" x 1/2" piece of

wood, add the insert and glue this to the back of the box for tripod

mounting. The thread insert works better than a T-Nut which is often be too long

or short. Thread inserts are adjustable so the female threads are flush with the

mounting surface. Dana

is studying a Mute

switch location and a different Lev Antenna mounting technique so hang

around. Their locations on the box will be added to the template.

Velcro

or screw mount the two plastic antenna

holder brackets to box or ? After

drilling holes check the alignment of the PCB Jacks to the box holes, if not accurate read Dana's Notes below.

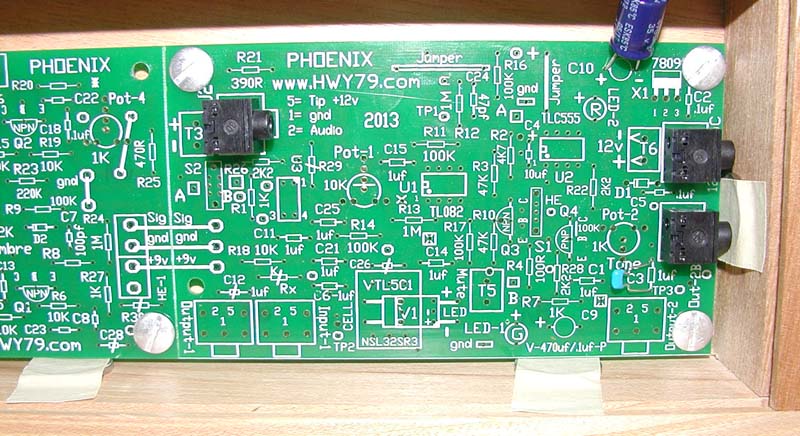

The board is placed in the wood box with

nickels in place to match the template for positioning and gluing.

The holes are not yet drilled in this photo

Stand-off stud & screws are staggered at the board score.

The three required Jacks are shown, Mount with extra lead length (1/2")

for C10 to move it outside for clearance of the J2 cable and extra for C3

to be used as a test connection. Nickels are used with masking tape so the

board position is accurate for gluing the mounting studs. Firmly (not

tight) attach

the five screw/studs to the PCB before gluing into position. Apply epoxy around

the stud edges for adhesion to the wood base while avoiding

the screw threads.

It is

important the aluminum screw is first threaded into a #8 steel nut and the

aluminum studs have a #8 steel screw threaded through them. This is to clean contamination off the threads, the aluminum pieces together

slightly dirty can seize together! Test each combo before securing them to

the board. Finger tighten firm.

Dana's Notes:

(SewerPipe) By following these

steps the position of the PCB placed in the box can be “Shifted” a slight amount,

the Plugged in cables help “Align” the PCB in the best position

for off centered holes. 1. Mount stand-offs

(screw/studs) to the printed circuit board, finger firm but "not" tight (no epoxy yet) 2. Place PCB in

the box and study the position and fit. (no epoxy yet) 3.

Plug the cables into the Jacks through the drilled out holes B C (F if used) in the wood box. 4.

Proceed if you have

proper clearance, otherwise you may need to elongate one of the holes for a better

fit.

5. Unplug the cables from the Jacks and lift out the PCB and apply the epoxy around the bottom

edges of the stand-off studs with a Q-Tip, avoid

the threads. 6.

Place the pc board back in its proper position, plug in the cables at B C (F if used)

and position the board. 7.

Carefully weight down the PCB and let the epoxy cure overnight.

Using jacks/plugs can help position the PCB in its final location for

gluing if your

holes did not have precision alignment.

From Amazon

Purchase two of the shorter boxes shown beneath the longer one - $11 ea.  This

needs study, if

the longer box is

used it leaves a space for a pitch

preview amp or

something? (-' To use the same drill hole template unmodified

the add-on accessory could occupy the top portion of the enclosure box

away from the L2 antenna side. This

needs study, if

the longer box is

used it leaves a space for a pitch

preview amp or

something? (-' To use the same drill hole template unmodified

the add-on accessory could occupy the top portion of the enclosure box

away from the L2 antenna side.

Template needs +

for a Mute Switch location, needs some

study.

(-'

Possibly two

holes by the Vactrol, one for the green LED-1 which also indicates Muted

when off and switch up Un-Mutes. Needs study. The

same two holes on Pitch board one could be for the red LED-2 which allows

proper Null point distance setting when Volume is Muted. The second hole

for ?

Using the side mounting

allows the back side of the enclosure to face the audience as an ideal surface to mount a wood carving or something

artistic.

<=Main

Page

|